The Sample Planning Module (SPM) can be used in conjunction with the EQuIS AQS Module to plan, schedule, and track recurring equipment-related activities. Plan and schedule activities associated with each monitor, even when multiple monitors are present at a single location. Equipment QA, calibration and maintenance activities can be planned and scheduled as Activities (aka equipment parameters) in SPM. Activities in SPM are synonymous with responsibilities that need to be completed during an event. In general, an Activity is something that should be done and recorded, but does not directly relate to the collection of a sample. Examples of activities include cleaning air filters, taking photos, trimming flora, site maintenance, taking initial vs final readings, and calibration checks.

Note: Before activities can be assigned to equipment, the DT_EQUIPMENT.SYS_LOC_CODE field needs to be populated for each EQUIPMENT_CODE. If an equipment does not have an assigned location, it cannot be selected in the SPM Activities window. |

|---|

Complete the following steps to use SPM with the EQuIS AQS Module.

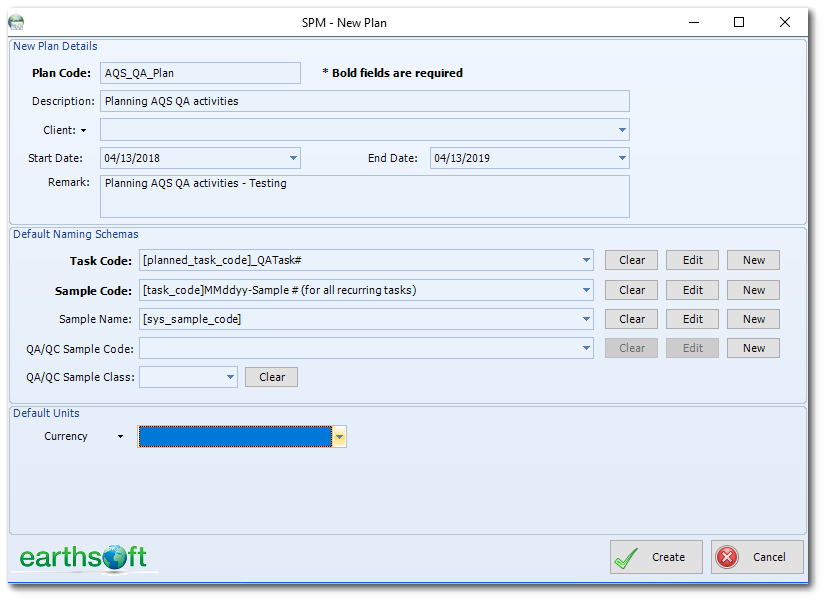

1.Create an SPM Plan for the desired AQS activities. See the Create a New SPM Plan article for more details.

2.Setup the activity tables according the instructions in this article.

Note: In the EQuIS AQS Module package, there are example AQS_EDGE_ConfigurationEDDexample.xlsx and AQS_ReferenceValueEDDexample.xlsx files that can be used. These EDD files contain some example ACTIVITY_CODES and ACTIVITY_TYPES that may be useful for AQS. |

|---|

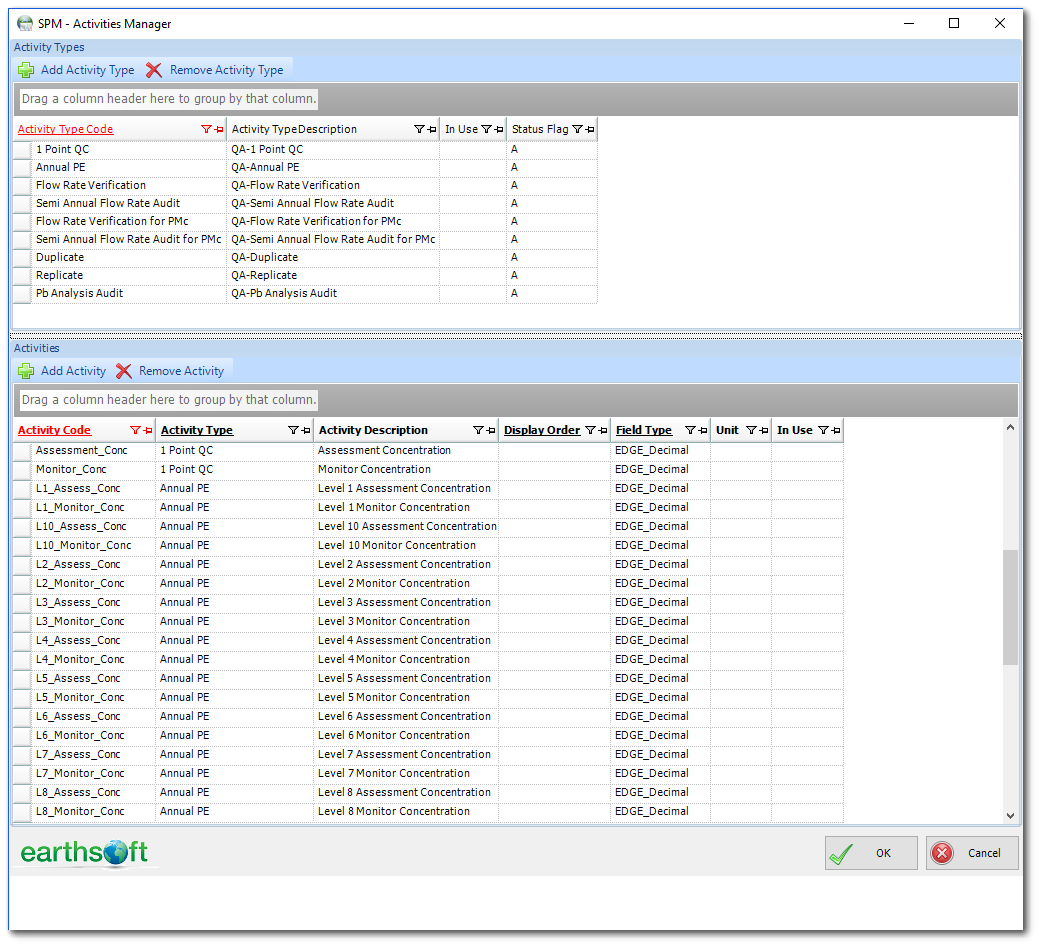

a.The ACTIVITY_TYPES setup in SPM will become the name of the sections that can be added to an EDGE EquipmentParameter Form. These forms can be used for AQS QA Transaction data collection. If you prefer to separate each AQS QA Transaction onto its own form, then this can be done by showing a single section per EquipmentParameter Form.

Example QA Activity Types:

•1-Point QC

•Annual PE

•Calibrations

•Flow Rate Verification

•Maintenance

•Pb Analysis Audit

•Semi Annual Flow Rate Audit

b.The ACTIVITY_CODES setup in SPM will become the fields in each Activity Type section. Activity Codes have to be unique across the database. The complete list of ACTIVITY_CODES can be found in the RT_EQUIPMENT_PARAM_TYPE and RT_SPM_ACTIVITY tables in the database.

Many ACTIVITY_CODE examples are included in the AQS_EDGE_ConfigurationEDDexample.xlsx and AQS_ReferenceValueEDDexample.xlsx files. Depending on your workflow and data requirements, you may prefer to add some but not all of the activities. One of the benefits for using SPM is the ability to track completeness with the SPM – Completeness Report Detailed. As you setup SPM, consider what you may want to see on that report; whether all the activities in the example Excel files or only a small number of activities need to be tracked to indicate completeness. In the Collect Templates, Required fields can be set so users will not be able to submit their dataset without fulfilling those requirements. Thus, completeness tracking and SPM setup can be easier by not needing to assign all activities to equipment because the appropriate data will be captured with the Collect Form submission.

For each ACTIVITY_CODE, users can specify the type of data expected (e.g., EDGE_Decimal, EDGE_Integer, EDGE_Text, or a custom enumeration list; a complete list of the available FIELD_TYPES can be found in the Setup Activities Tables article).

Examples:

•For the “1-Point QC” AQS QA Transaction, the following data needs to be collected and reported. Other ACTIVITY_CODES can be added depending on the data collection process.

•Assessment Number

•Reported Unit

•Monitor Concentration

•Assessment Concentration

•For the “Annual PE” AQS QA Transaction, the following data needs to be collected and reported. Other ACTIVITY_CODES can be added depending on the data collection process.

•Assessment Number

•Reported Unit

•Monitor Flow Rate

•Assessment Flow Rate

3.If applicable, setup the Lab Contract(s).

4.Add Planned Tasks for activities and/or samples

a.Set recurrence pattern or select custom dates.

b.Review resulting schedule.

c.Assign Activities and/or Samples.

5.Add activities to a planned task using the instructions in this article. Assign activities to either a location (SYS_LOC_CODE) or to an EQUIPMENT_CODE.

Note: All equipment needs an assigned DT_EQUIPMENT.SYS_LOC_CODE. |

|---|

a.One or more at a time.

b.Use Calendar view to see all tasks in the Plan.

7.Export plan information for use in Collect or EDGE by running the Collect Field EDD Report or the EDGE Field EDD Report, respectively. These reports create an EDD to assist field crews in recording field data. The reports create an EDD with a list of the samples and activities planned for each location, equipment, and task. When used in conjunction with SPM, data fields relating to scheduled activities can be pre-populated, reducing the amount of time spent in the field entering these data.

The EDGE Field EDD report can be run from the Reports menu ribbon in SPM. Both reports can be run in EQuIS Professional.

8.The Plan and Tasks are now ready for use. When ready, enter data into EQuIS via an EDD from Collect, EDGE, or EDP.

a.Labels and COCs can be pre-printed, if applicable.

b.SPM Task Details and SPM Calendar export reports are available.

9.Use the SPM Completeness Report – Detailed to track status of AQS activities.

Note: The DT_SPM_PLANNED_ACTIVITY.TASK_CODE, DT_SPM_SCHEDULED_ACTIVITY.TASK_CODE, and DT_EQUIPMENT_PARAMETER.TASK_CODE fields need to be populated for proper tracking via the Completeness Report. The Collect Templates from the ECC are mapped to populate the DT_EQUIPMENT_PARAMETER.TASK_CODE field. |

|---|